Product Series

TGV310

Support hotline:

Category:

Gas Control Valve

- Product Description

-

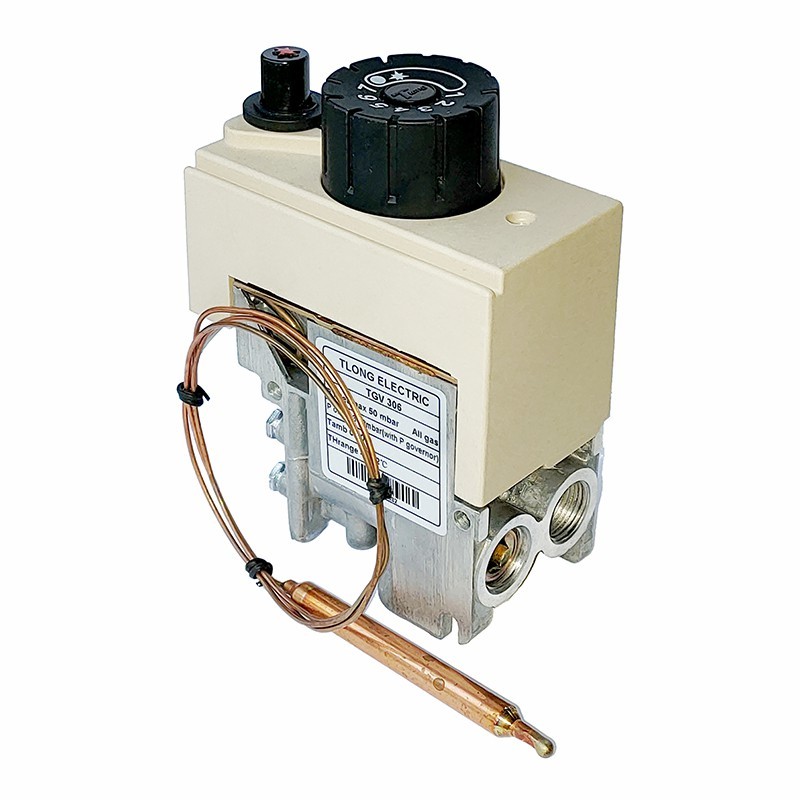

- Commodity name: TGV310

The TGV310 is suitable for use with stoves, boilers,catering equipment and room heaters.

Application

• The TGV310 is suitable for use with stoves, boilers,catering equipment and room heaters.

General data

• Construction characteristics

• Auminium alloy body

• Inline inlet and outlet (straight and elbow flange available)

• Bottom outlet (optional)

• Pilot gas rate adjuster

• Pressure regulator or as an alternative flow adjuster

• Inlet and outlet pressure test points (optional)

• Inlet and pilot filters

• Piezo-electric igniter (optional)

• Four mounting holes

Main features

• Thermoelectric flame supervision device.

• Pressure regulator

• Temperature control

Reference standard

• En126

• Multifunctional device for gas burning appliances

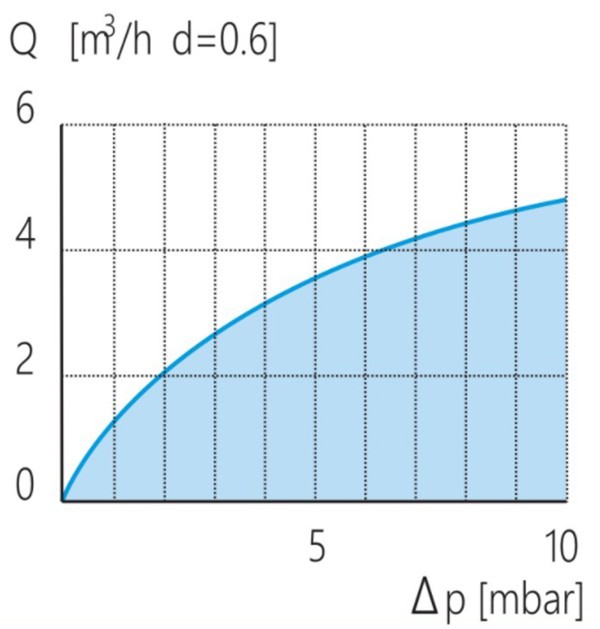

Flow rate q as a function of pressure △P

Gas family Q △P I d=0.45 3.9 m³/h 5 mbar II d=0.6 3.5 m³/h 5 mbar III d=1.7 4.4 m³/h 5 mbar

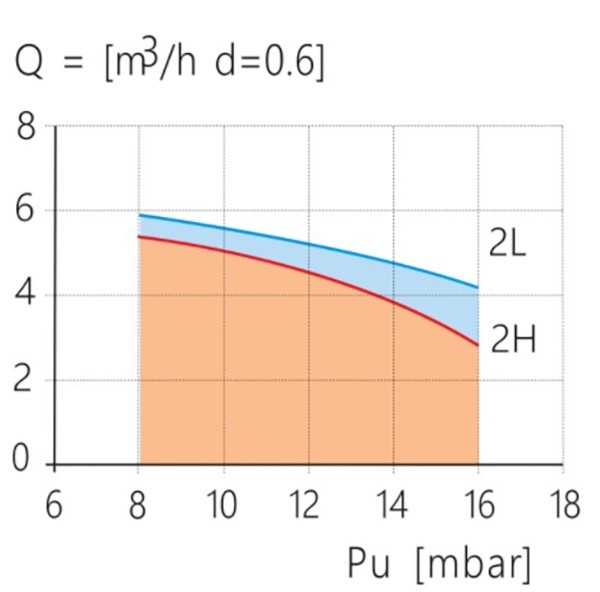

Regulated flow rate Q

Inlet pressure range (mbar)

Gas family Nominal Maximum Minimum 2H 20 25 17 2L 25 30 20 Outlet pressure tolerance +10% -15%

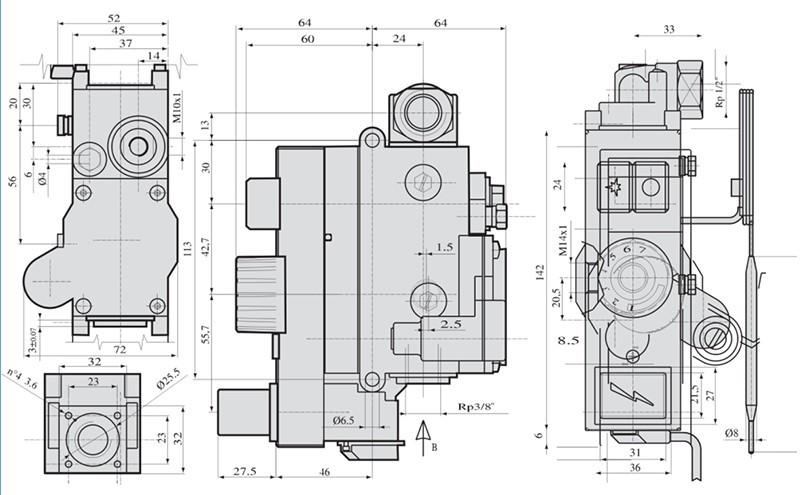

Dimensional dranwing

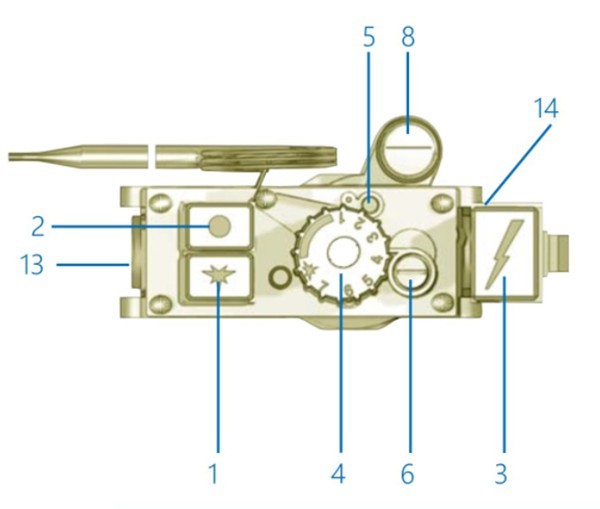

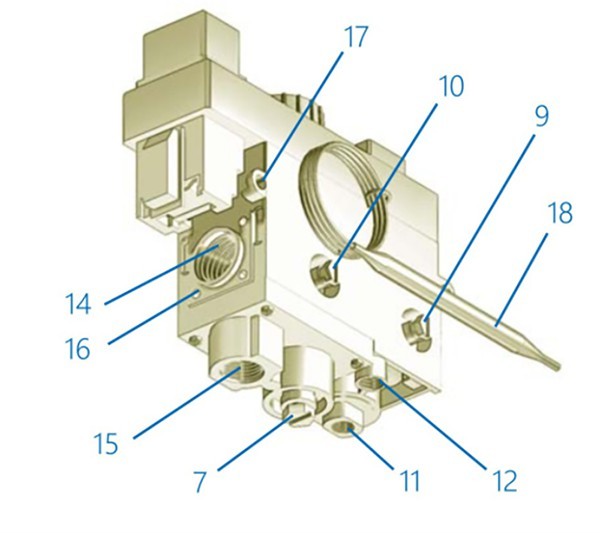

1. lgnition button 7. Maximum flow setting screw

(versions with flow adjuster)

13. Gas inlet 2. Shut-down button 8. Oulet pressure setting screw

(versions with pressure regulator)

14. Main gas outlet 3. Piezo-electric ignition button (optional) 9. Inlet pressure test point 15. Bottom gas outlet 4. Temperature setting knob 10. Outlet pressure test point 16. Flange fixing holes 5. Pilot flow setting screw 11. Thermocouple connection 17. Mounting holes 6. Minimum flow setting screw 12. Pilot outlet 18. Thermostat bulb

Fig.3: version with pressure regulator

and piezo-electric igniter.

Fig. 4: version with flow adjuster

and piezo-electric igniter.Thermostat data

Use specifications

Mounting position

Gas families

Ambient temperature

Maximum inlet pressure

Bending and torsion resistance

any

I, II and III

0...80℃

50 mbar

Group 2

Mechanical connections

Gas inlet and outlet

Pilot outlet

Thermocouple connection

Pressure test point

Flange fixing holes

Mounting holes

Rp½ or Rp3/8 ISO 7

M10x1 for tube φ 6, φ 4mm, φ1/4

M9x1 or M10x1

φ 9mm

M4 x 7mm

φ 6.5 mm

Flame supervision

Number of cycles expected : > 10000

Lgnition time : < 10s

Shut-off time : < 60s

Pressure regulation

Direct pressure regulator: Class B

Outlet pressure setting range(optional): 3... 1 8mbar(15...30mbar)

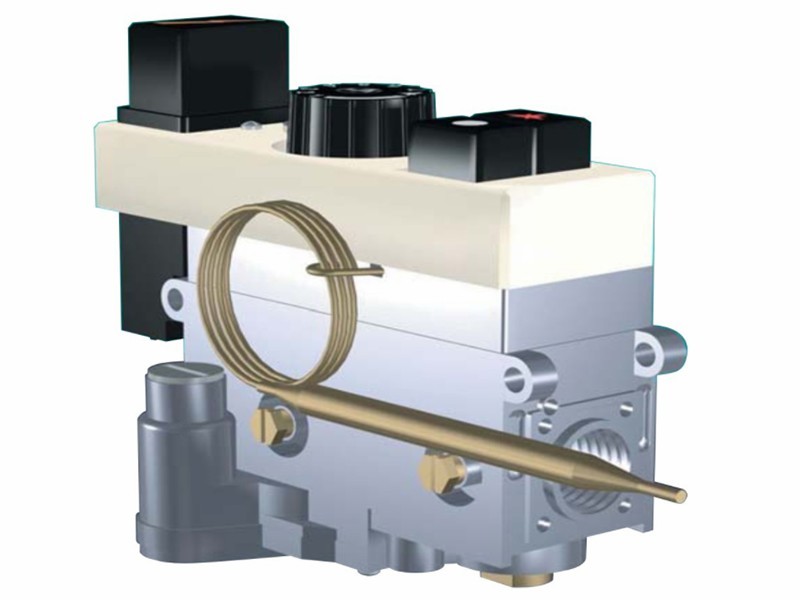

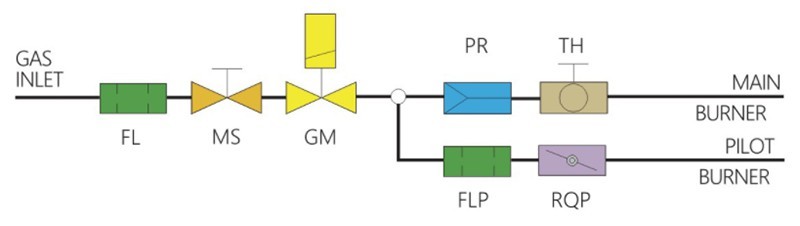

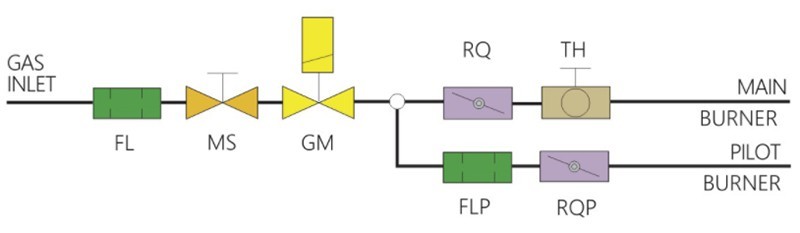

Valve Description

Fig.1: Version with pressure regulator

Fig.2: Version with flow adjuster

• FL is the inlet filter

• MS is the operation push button

• GM is the thermoelectric flame supe-rvisior device

• FLP is the pilot filter

• RQP is the pilot flow adjuster

• PR is the pressure regulator

• RQ is the main gas flow adjuster

• TH is the modulating thermostat with on/off function with temperature selecting knobKeywords:- Gas Control Valve